Glidlager Bussningar.PDF

![]()

bimetal bearings is composed of a specially customized surface layer of PTFE formulations and is specifically applied for the high PV bushes of gear oil pumps.

What is DU composite bearing?

Composite dry sliding bearings are primarily used for bearing arrangements where heavy loads have to be supported and where rotational or oscillating movements are relatively slow.

Where to use DU composite bearing?

- Because of their good sliding properties and compact design, these plain bearings are particularly suitable for bearing arrangements where:

- Maintenance-free operation is a prerequisite

- There is a risk of lubricant starvation

- Lubricants cannot be used or are forbidden

- Space is limited.

Why choose du composite bearing?

- Maintenance-free operation

- No lubrication required (PTFE composite)

- Initial lubrication required (POM composite)

- Minimum wall thickness, minimum space requirements

- Accommodation of heavy loads

- Wide range of temperatures

- Good sliding properties

- Virtually no stick-slip

- High wear resistance

- Less sensitive to edge loading (POM composite)

- No machining required.

Which other bearings we can supply to you:

Our sliding bearings including:

| SF-1(du) oilless bearing bushing (PTFE Composite) |

| SF-2(dx) slide bearing bushing (POM Composite) |

| FB090(FB090G) bronze bushing |

| FB092 bronze bushing |

| JDB,JFB solid graphite lubricating bushing |

| JF bi-metal bushing |

| FU sintered bronze or iron bushing |

| FZ POM/Al/Cu ball cage retainer |

| FR metal mesh+PTFE Soft strips |

| JGB Graphite bearings |

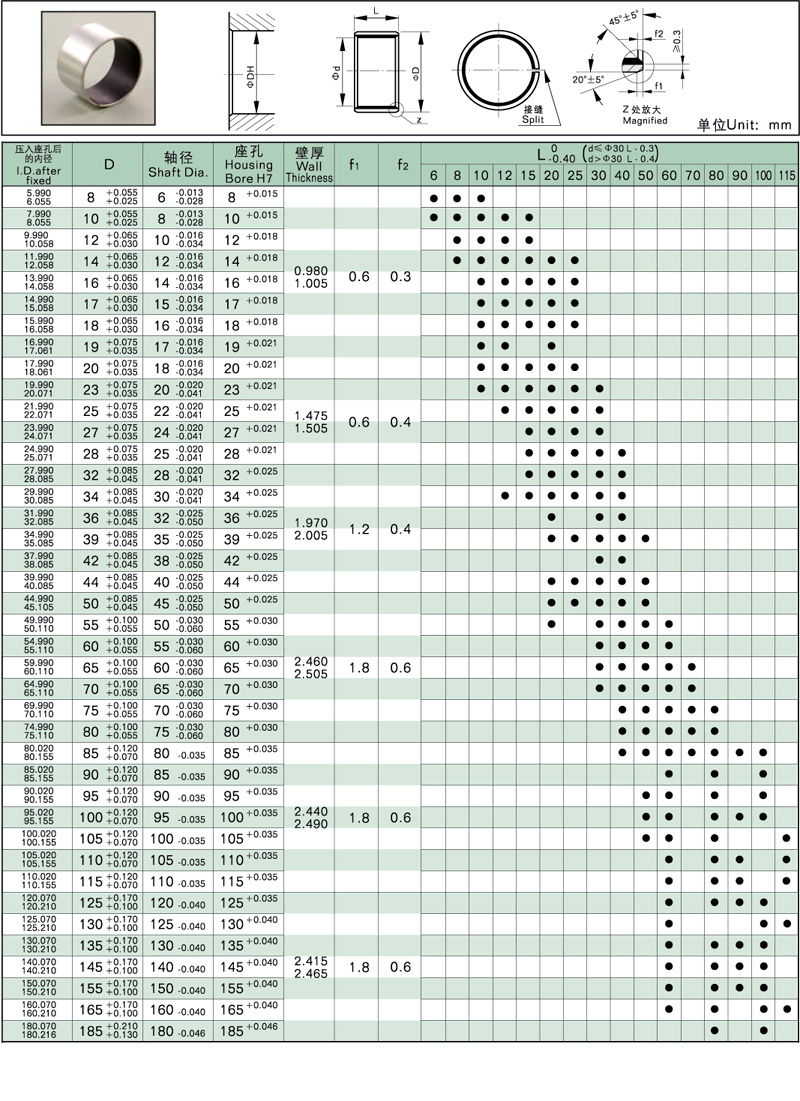

DU Compsoite bearing standard sizes list for your reference

General introduction of us

We are a professional manufactuer on various kind of bearings in China for over 14 years already.

With updated machinery and skilled staffs we have supplied stable high quality products to customers all over the world.

Our experianced engineers and exporting team can answer your inquiry or comment at the first time,and providing professional service from factory visiting, making orders to deliver goods.

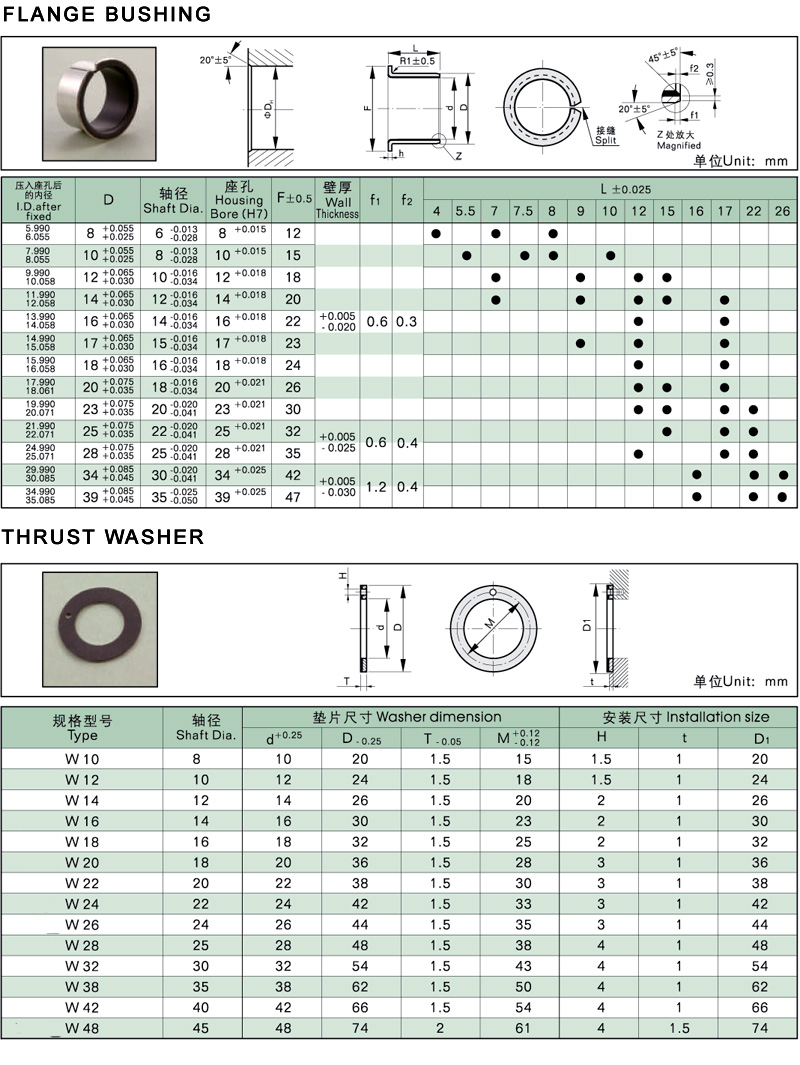

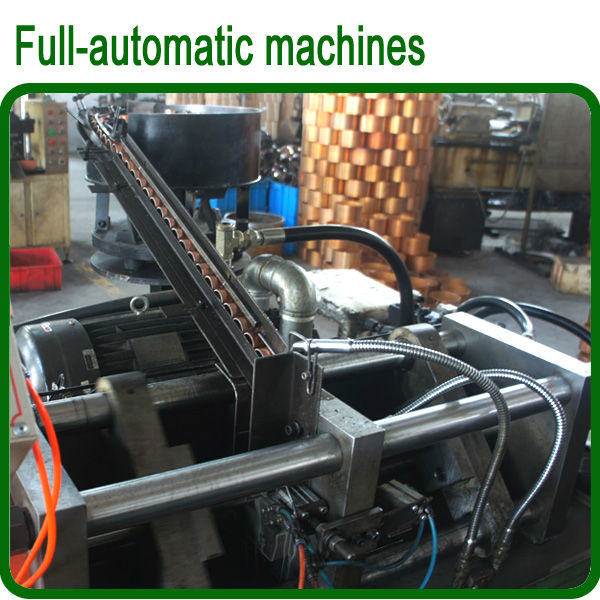

RIght now, we have over 100 skilled staff and different kinds of machines including automatic production lines,later machine,milling machine,CNC machine etc.

This picture showing our staff structure and basic machines list

This picture showing updated sintering machine and skilled workers in production

Our workshops are welcome you visiting:

This is our workshops buliding

We are using full new high quality raw materials only.

This is the bronze powder-steel backing sintereing line

This is a full automatic chamfering machine

Detail packing steps:

1.Clean bearings in anti-rust oil

2.Plastic films packing bearings to rollers

3.Bearings rollers put into plastic bag

4.Cartons with goods information label

5.Pallet for every 12ctns/24ctns/36ctns

Our packings are suitable for FCL or LCL sea shipping.

MOQ:1pc or 100pcs or 1000pcs(Different model and size have different requirement)

Delivery: you can choose different delivery ways for different qty orders.

Our quality management:

We will make inter inspection on every step of production.

Also you can order inspection company monitoring our production in our workshops.

1.ISO/TS 16949 Production Quality Management Certification

2.We will make measure guages calibration every 6 monthsGlidlager bussningar

3.Record of calibration in certified lab

4.Certificate of lab