Product Range – Wear Plate Solutions by Alloy Steel

Traditional Wear Products. There are an abundance of wear plate and liner solutions available. Some wear plate simply uses old technology that does not meet modern …

[PDF]

Friction Coefficient and Wear Rate of Copper and …

34 Dewan Muhammad Nuruzzaman and Mohammad Asaduzzaman Chowdhury that of curve 1. Also, aluminum disc takes about 23, 21 and 17 minutes to stabilize when the

Slide Plates – PT&P Products – Piping Technology …

Slide Plates . Piping Technology & Products supplies slide bearing plates for a variety of applications including support of piping, heavy equipment such as pressure …

PE-UHMW 1000 vs PE-HMW 500 – SlideShare

Apr 02, 2012· PE-UHMW 1000 vs PE-HMW 500 1. PE-UHMW 1000 & PE-HMW 500 Diversity Familiar with this situation ????? Which material I should use? PE-UHMW …

FAQ | SLIP Plate

Dry film lubricants will wear away over time but at a much slower rate compared to wet lubricants. This provides a more consistent friction management system to give …

[PDF]

Steel Solutions for wear and impact resistant applications

6 Our products Relia® Quality Wear Resistant Plates Relia® is a range of high hardness, conventional low-alloyed martensitic steels, which obtain their hardness …

Wear Resistance – Professional Plastics

Plastic Bearing materials include; Delrin, Nylon, Acetron GP, Acetron NS, Ertalyte TX, Turcite, Rulon, UHMW, Fluorosint 207, Tivar and other wear resistant plastic …

Titanium Alloys – Wear Resistance

Jan 30, 2002· The wear resistance of titanium alloys is quite poor. It can be enhanced by any number of surface treatments such as enhanced surface films, conversion …

Hard wear surface for 17-4 PH stainless steel, or wear …

The finishing.com Hotline: Serious Education … plus the most fun you can have in metal finishing. Ted Mooney, Webmaster Hard wear surface for 17-4 PH stainless …

The Tribology of Contact Finishes for Electronic …

Jan 07, 2014· The Tribology of Contact Finishes for Electronic Connectors Part I: Mechanisms of Friction and Wear

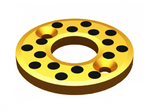

dubushings

Our company is a professional manufacturer on various kind of bearings in China for over 15 years.If you are interested in our company's bearing and want to get the relevant information. You can consult our number: 0086-731 84770165, Email:bushings@slide-bearing.com or left click on the website customer service online consultation.

You may also like...

-

ge 6 e joint bearings

19 Jan, 2018

-

-

Reciprocating Motion Bushing

1 Aug, 2018

More